CapitaSpring development, at 88 Market Street, is scheduled to complete next year, a 280mhigh development that will feature Singapore’s highest urban farm. Designed by award winning architect, Bjarke IngelsGroup (BIG) in collaboration with Carlo RattiAssociati, who have conceived numerous high-profile developments globally, the development realises CapitaLand’s vision of blending indoor and outdoor spaces within the urban realm. In an article by (The Straits Times), Mr Ingels mentioned that “Elements like the Green Oasis and the rooftop garden all reveal themselves to the outside by breaking apart the regimented geometry of the facades”. Mr Carlo Ratti, founding partner of Carlo RattiAssociati, adds: “What we’ve seen in the 21st century is a lot of sprawl.Cities moving outside into the countryside and into nature,” he says.“But we can do the opposite today –we can bring nature inside our urban cities and even inside our buildings.”

Aaron Lefcovitch, a Director at Windtech Consultants says “While the concept of shifting nature into buildings drastically improves the human experience and overall wellbeing of those privileged enough to operate in the space, this does bring with it some unique engineering challenges, as we now need to ensure that the internal space is protected from the elements”. One of the key design features within the ground level foyer, is a complex interconnected hanging sculpture designed by Argentinian artist Tomas Saraceno (in collaboration with Esther Schipper), with the structural design undertaken by Art-Engineering. The team were acutely aware that there was no feasible way to determine the wind loads on the art-structure using traditional methods, and that the wind loads would be a key input to the design, important not only for the aesthetics (the frame needed to be as slim as possible) but also for ensuring the art work would not spin into a tangle.

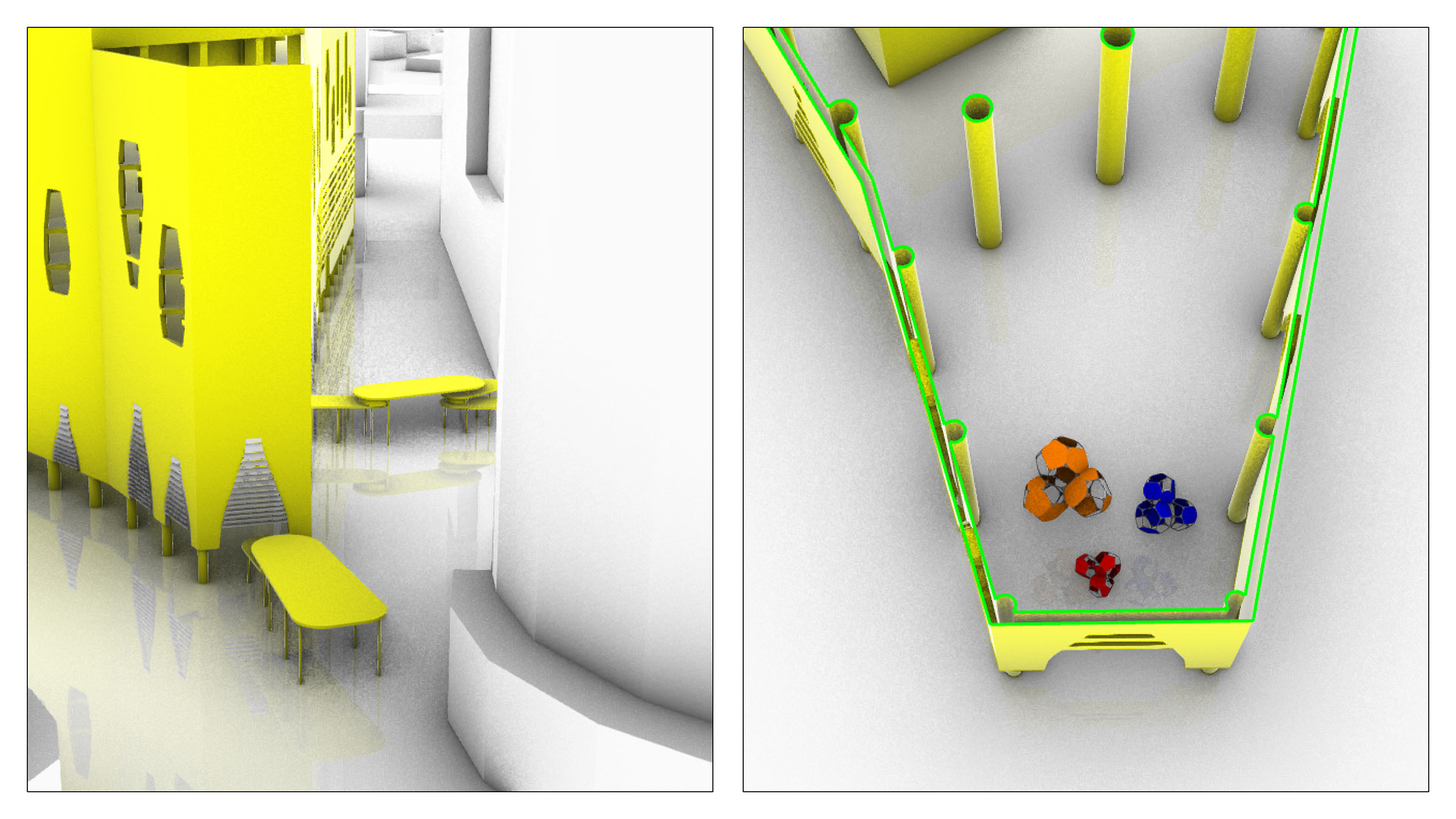

Figure 1. Artist’s Impression of Ground Level Foyer (Image: CapitaLand)

From the outset, Windtech’s team of specialists had recognised the challenges posed by this project as neither wind tunnel testing nor Computational Fluid Dynamics (CFD) alone would have provided a sufficient level of accuracy, given the scale and geometric complexities of the artwork. The key reason for the apparent complexities were due to the wind loads heavily depending on the following:

Figure 2. Extent of CFD Model Used to Determine Wind Speeds at Artwork Location

Wind tunnel modelling has its limitations with regards to the need for a minimum characteristic dimension of the artwork to achieve similarity of flow around the model at scale: In this case a scale of around 1:20 would be required. As the art installation is within a semi-enclosed space within the building, it would also not be possible to achieve the required accuracy by modelling the artwork in isolation from the surrounding buildings as the surrounds heavily influence the localised wind effects. Consequently, and assuming a 1:20 scale model with surrounding buildings modelled to a diameter of 700m, the wind tunnel model would have needed a span of 35m. For this reason, a wind tunnel only approach would have been impractical.

Furthermore, obtaining accurate flow conditions in the wind tunnel at the artwork location using the smaller scale model only would also be problematic, as Reynolds Number effects as well as the effects of model surface friction would result in a significant underestimation of the local wind speeds.

Hence, Windtech’s specialists concluded that the only way to achieve the required accuracy was to employ a hybrid approach, utilising the strengths of both the wind tunnel and CFD.

Figure 3. CFD Model of the CapitaSpring Foyer and Cloud Sculpture

First, the wind tunnel model study at 1:400 scale was used to establish the accurate flow conditions in the “outdoor” areas just outside of the perimeter of the semi-open atrium space. Then Windtech then set out to replicate these flow conditions using CFD. This proved to be a very challenging task given the geometric complexity of the development site and surrounding buildings. The solution was a 1:1 replication of the wind tunnel model and surrounds in the CFD domain and a variety of tested numerical flow simulation types. Given the number of simulations required, the final size of the CFD model volume, and the very fine mesh elements needed to model the flow around the location of the artwork, an enormous amount of computational resources was consumed, made possible through the utilisation of a super-computer. The above was necessary to ensure that the results were accurate, and our team were confident that we were achieving flow similarity for the various wind angles tested.

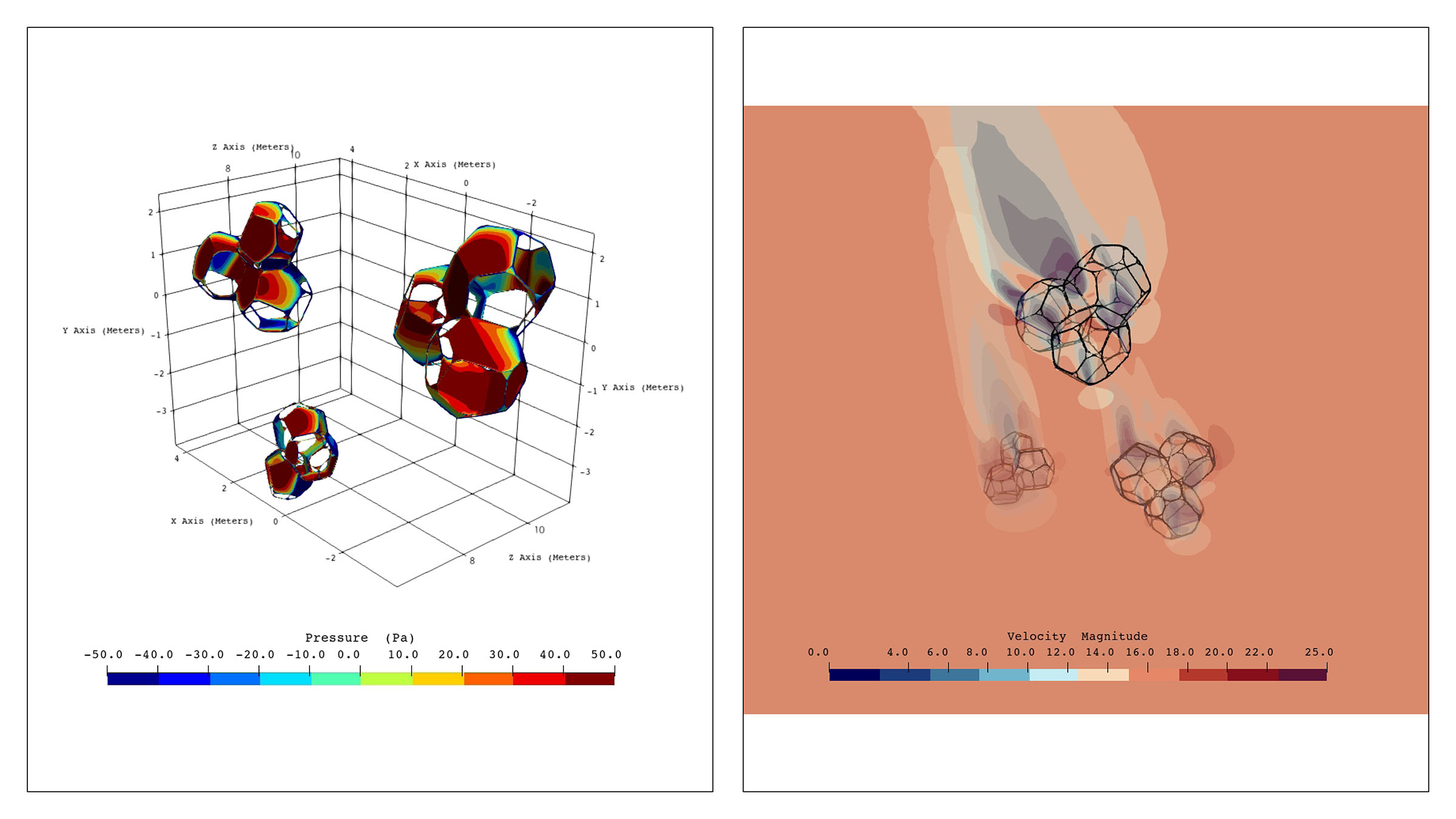

The next step was to extract the localised 3D wind flow boundary conditions (in the form of x, y and z components of the mean and gust wind speeds). These boundary conditions in conjunction with two phases of CFD simulations (the artwork in isolation and three artworks combined) enabled us to determine the pressure distribution over the surface of the artwork, which is particularly important as it informs us whether there is a potential for the artwork to twist on itself.

As a side note, determining the pressure distribution over the surface of the artwork using wind tunnel testing would be problematic due to the difficulty in concealing the pressure taps that are required to feed the pressure signal back to a pressure acquisition system. It is important to conceal these tubesso that they do not interfere with the localised wind flow.

Figure 4. Pressure Distribution on Cloud Sculpture and Wind Speed Contour

This project shows what is possible when leveraging the power of both physical testing in the wind tunnel and high-performance Computational Fluid Dynamics (CFD) models to determine accurate load cases on a complex structure.

Furthermore, it demonstrates Windtech’s capabilities in CFD, which led by Dr Niall O’Sullivan in Windtech’s London office has carried out advanced and extensive testing across an immensely broad spectrum of applications.

For more information on our capabilities in the Wind Tunnel Testing and/or CFD space, please reach out to any of our global offices at: https://windtech.com.au/contact-us/

Quality Assurance Manual for Wind Engineering Studies of Buildings

Dr Nicholas Truong to Present at 8th Annual Vertical Cities Conference

CTBUH Best Tall Building in Asia and Australasia Award CTBUH Urban Habitat Award

Construction of the world’s tallest modular building is nearing completion in Singapore. The building is quite remarkable in that it uses a Prefabricated Pre-Finished Volumetric Construction (PPVC) system. PPVC is a method in which free-standing volumetric modules (complete with finishes for walls, floors, and ceilings) are prefabricated and then erected onsite. Much of the construction is done offsite in a controlled environment where productivity and safety are optimal and dust pollution is minimized.

Each tower is 459 ft tall, and combined they are made up of 1,899 modules with each module weighing between 16 and 30 tons or approximately the weight of 10-20 family size cars. The contractor required special cranes which could handle higher than normal loads than would be expected on a regular construction site.

In April 2016, the Singapore government awarded Dragages Singapore the contract to design and build Clement Canopy. In an interview with BD+C, Aurélie Cleraux, Bouygues Bâtiment’s head of modular construction indicated that more than 60% of the two towers’ superstructure was built offsite. The project required a total of 48 module shapes and the modules were cast by a concrete precast manufacturer in Senei, Malaysia, in five days. The fitouts were completed in the contractor’s factory in Tuas, Singapore, within 15 days. The modules included mechanicals and plumbing, plastering, painting, and bathroom fixtures and tiles.

Cleraux explains that there is a big push by the Singapore government to improve construction productivity. And the benefits of modular and prefabrication processes, he says, are that they can reduce construction time by up to 50% and reduce onsite labour by 30%. Other benefits include reduction of jobsite noise, pollution and neighbourhood disruption; improvements in jobsite safety and the quality of the finished product, as well as the possible reuse of the building’s materials down the road.

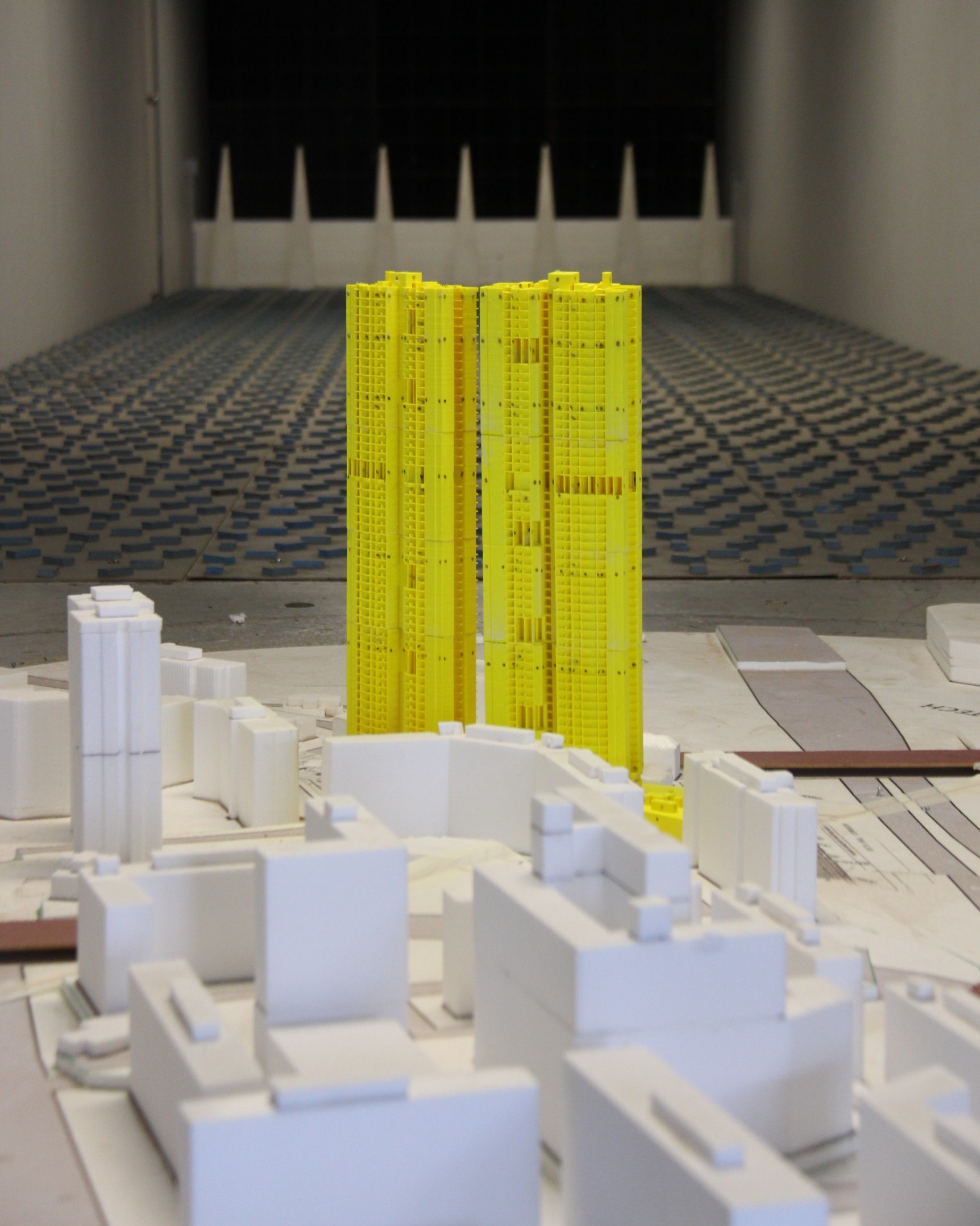

Windtech Consultants, headquartered in Sydney, have had the privilege of providing comprehensive wind engineering services on the Clement Canopy, with work being co-ordinated by their Singapore Office. Aaron Lefcovitch, Director and regional manager of Asia says, “It was first thought that there were going to be some challenges in getting the building to behave from an occupant comfort point of view, as a modular structural design tends to exhibit lower than normal natural frequencies. However the relatively high structural density, and the fact that we are using advanced directional analysis techniques meant that the building accelerations were within the prescribed occupant comfort criteria.”

Aaron went on to say, “Improved accuracy in the final load cases is achieved by conducting an in-depth analysis of the assumed damping that could be expected for a structure, which varies with return period. We use published data which correlates the building’s tip deflection with assumed damping levels. It is quite common to hear that structural engineers are given the responsibility to specify assumed damping for wind impact design, however at Windtech we use published data based on full scale measurements of a vast number of buildings to guide our assumptions. This takes guesswork out of the analysis.

Windtech Consultants would like to congratulate the whole project team for rewriting the record books on another fantastic project in Singapore. Singapore is truly leading the way by always keeping an open mind and embracing new technologies.

Quality Assurance Manual for Wind Engineering Studies of Buildings

Dr Nicholas Truong to Present at 8th Annual Vertical Cities Conference

CTBUH Best Tall Building in Asia and Australasia Award CTBUH Urban Habitat Award

Williamsburg officially has a new tallest tower. The construction of Ten Grand Street also known as 260 Kent Avenue is visibly complete, with its impressive crystalline façade and two-legged structure proudly forming the first part of the redevelopment of the Domino Sugar Factory site. This mega project comprises a six-acre site which until now had been inaccessible to the community for over 160 years.

Ten Grand Street is a 45-story, 435-foot-tall tower designed by world-renowned architect COOKFOX for Two Trees Management. The tower features interlocking buildings with white precast concrete façade inspired by the molecular pattern of sugar crystals, giving recognition to the site’s history as a sugar factory.

This tower joins the SHoP Architects-designed and fully leased 325 Kent Avenue project which opened last year and is one extra piece in the puzzle in a bid to change the Brooklyn skyline and revitalise the riverside area into a thriving mixed-used community, connecting the neighbourhood’s industrial past with the present.

Windtech Consultants, headquartered in Sydney, have had the privilege of providing comprehensive wind engineering services on Ten Grand Street, with work being co-ordinated by their New York and London offices. Windtech Consultants conducted a Structural Loads and Building Motion Wind Tunnel Study using a modified Multi- High Frequency Pressure Integration (HFPI) Technique which Windtech’s technical team published in 2007. This technique enabled an accurate and definitive assessment of the wind loads on the structural frame as well as a set of equivalent-static load cases taking into consideration the effect of load transfer between dynamically independent substructures via the rigid link at Level 22. Key to the accuracy of the technique is the ability to provide a set of load cases for each interlocking building sub-structure using load transfer influence coefficients extracted from the FEA model developed by the New York, based structural consultants, RGCE. These influence coefficients provide clarity on how loads are transferred between the sub structures. Multi-substructure analysis is not new, however a key difference between the outputs provided by Windtech Consultants and other wind engineering firms, is the additional effort put into presenting only the critical load cases (i.e. in the case of Ten Grand Street, a total of 36 load cases across both sub-structures) governing the design rather than leave the structural consultant to sift through 300 load cases in the case where the less sophisticated technique is employed.

In addition, Windtech Consultants deployed a sophisticated directional method as part of the analysis for this tower which enables the highest possible accuracy and draws on the full set of directional extreme wind climate data. Other directional methods used with wind tunnel data can either under or overestimate the design loads. The building accelerations were also found to be within the prescribed comfort criteria which is generally expected for tall buildings that are structurally linked at high elevations. This is largely due to the lack of correlation of the peak wind actions on the sub-structures.

Windtech Consultants would like to congratulate the whole project team for delivering yet another fantastic project that will have a meaningful impact on the Brooklyn skyline and serve as one piece of the puzzle in this amazing redevelopment project for the lucky residents of Williamsburg.

To hear regular updates via social media page, please visit our LinkedIn page and click on Follow.

Quality Assurance Manual for Wind Engineering Studies of Buildings

Dr Nicholas Truong to Present at 8th Annual Vertical Cities Conference

Extending the usability of outdoor spaces throughout the seasons is an essential consideration in any well-designed project. This is the case now more than ever as usable outdoor space promotes active and healthy lifestyles, improves the viability of outdoor businesses (i.e. restaurants) and improves the overall experience of users. The use of outdoor spaces for retail and restaurant use has recently become an important means of controlling the spread of contagions. It should also be noted that even moderate climates, neither hot or cold, can present challenges from a thermal comfort point of view which is a common misconception.

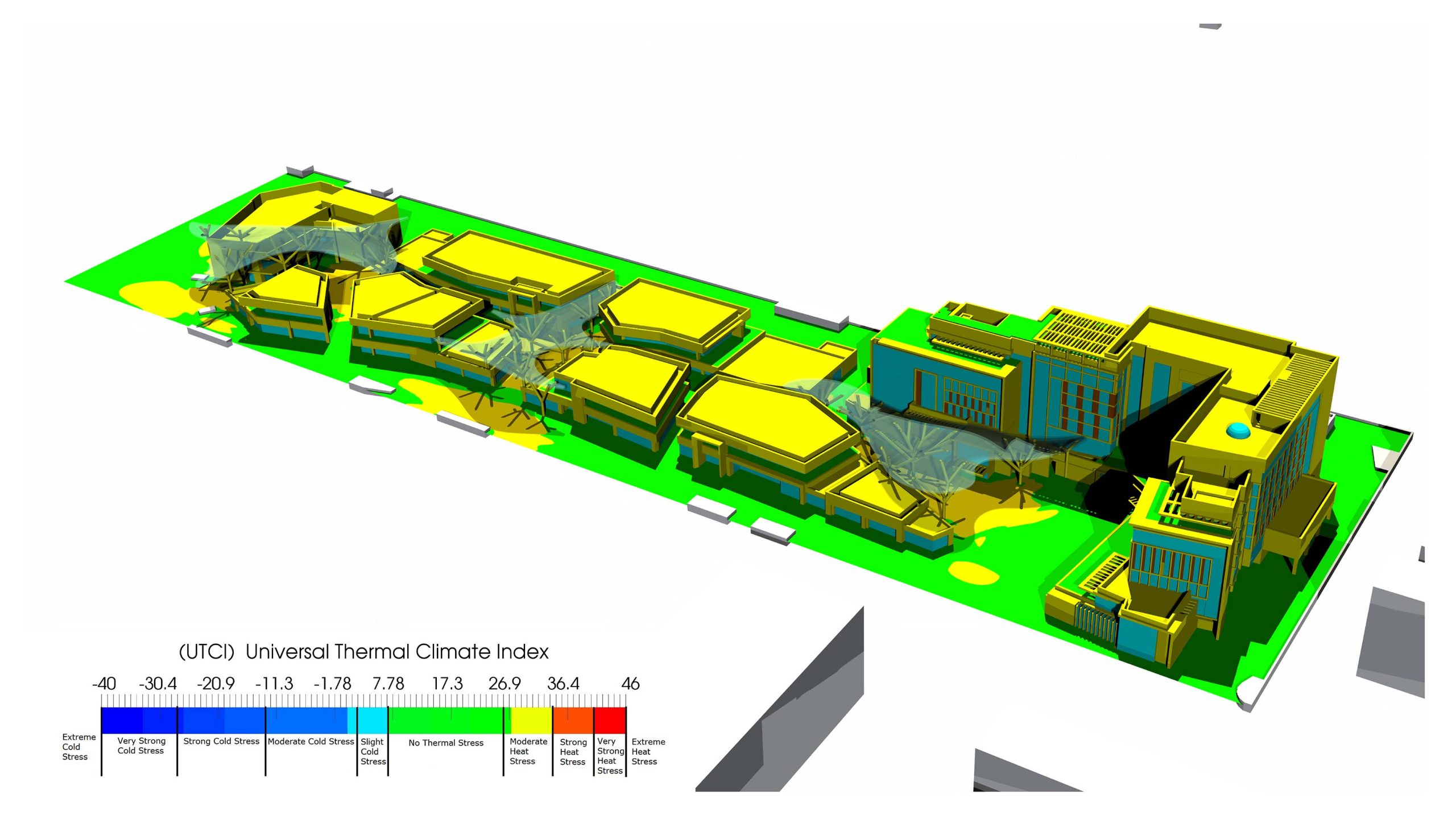

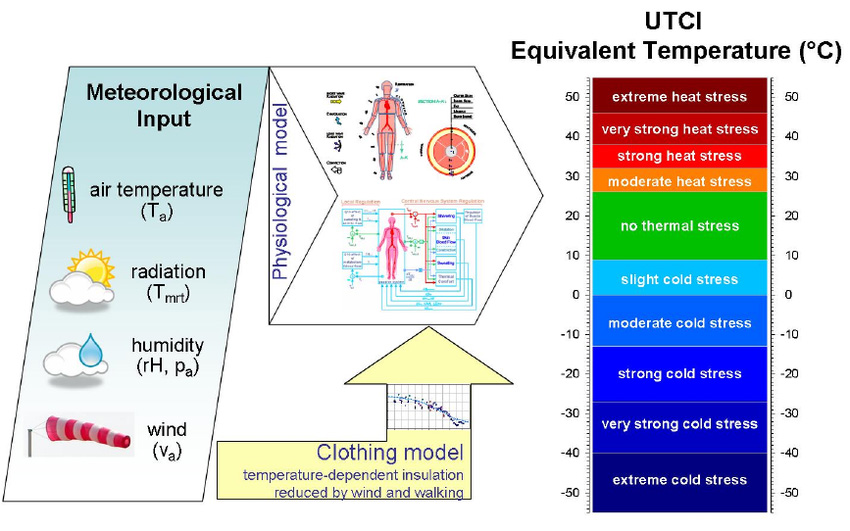

WINDTECH has undertaken detailed thermal comfort studies for a broad range of scenarios with experience on everything from small residential developments to large commercial developments (i.e. shopping malls). We use a range of metrics to assess thermal comfort including the Universal Thermal Comfort Index (UTCI) as indicated in Figure 1, which is one of the most widely recognised thermal comfort index globally. Our method of analysis accounts for solar load, humidity, wind, and the properties of building materials (i.e. glazing) throughout a development and results are presented in a way that enables accurate pinpointing of problem areas and effective identification of mitigation measures.

Figure 1. UTCI comfort criteria categories

The Universal Thermal Climate Index (UTCI) is a thermal comfort index used by COST to provide a measure of the perceived heat or cold stress of occupants. The UTCI is defined as the equivalent air temperature of an isothermal environment at a specific relative humidity, in which an occupant, wearing clothing to a quantitative level and at an activity level, experiences the same total heat loss from the skin in comparison to an occupant in the actual environment. Essentially, UTCI is a measurement of the perceived heat or cold stress of occupants and is calculated using the ambient temperature, mean radiant temperature, humidity, occupant activity, clothing level as well as airspeed, all measured at the occupant’s location. The model utilises heat balance principles to relate thermal comfort to ten key sensations.

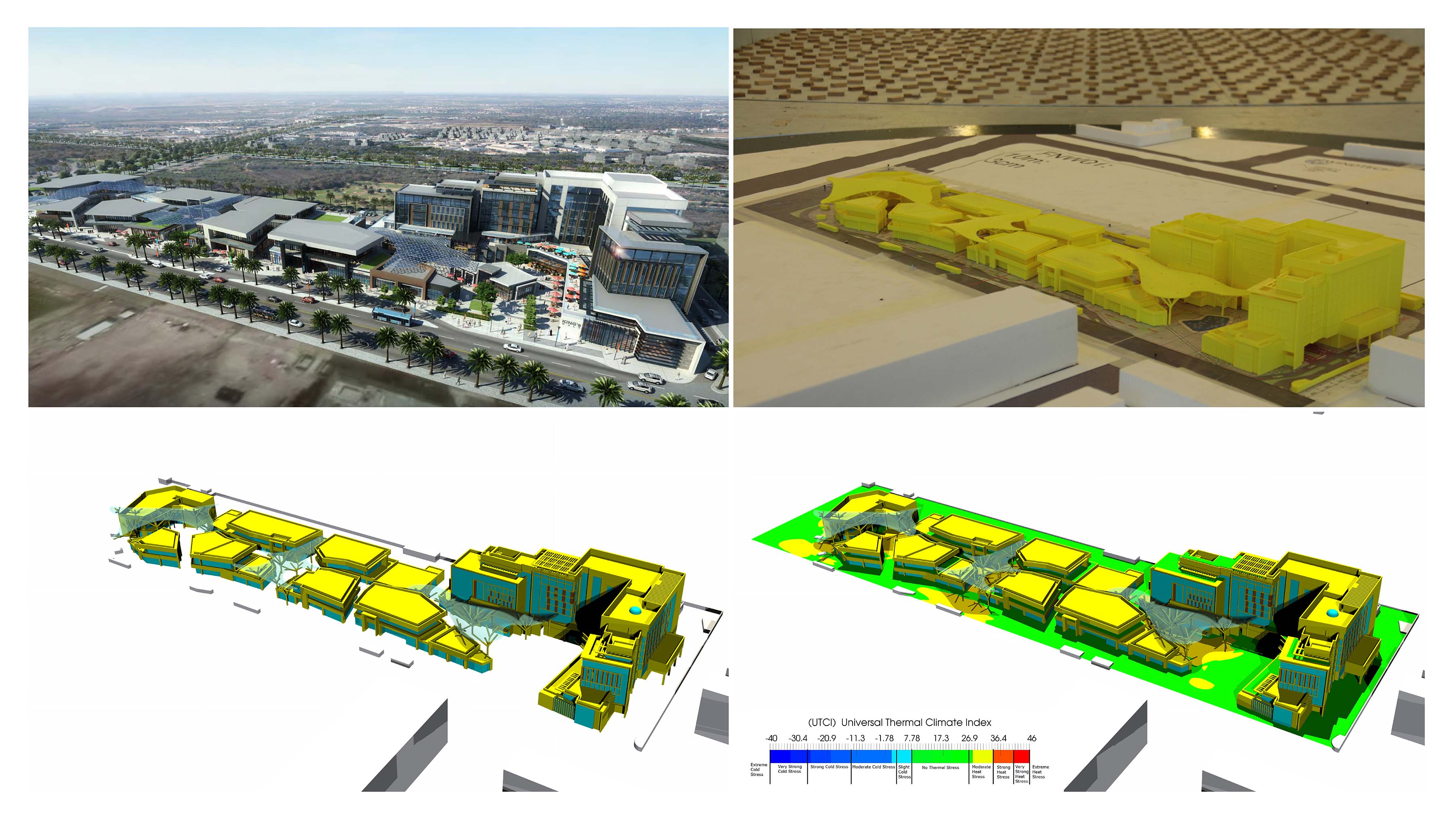

CASE STUDY 1: Kings Walk Mall, Jeddah, KSA

A hybrid wind tunnel and computational fluid dynamics (CFD) approach was undertaken to assess the outdoor conditions within the mall. This method leverages the accuracy of wind tunnel testing and the additional physics capabilities of CFD, enabling a level of detail and accuracy which otherwise would not be possible.

Figure 2. Kings Walk Mall, Jeddah, KSA – Architectural Impression, Wind Tunnel Model, 3D CFD outdoor wind and thermal comfort model with glazing and wood boundary conditions highlighted and Outdoor wind environment CFD ground level contour of UTCI (Universal Thermal Climate Index) accounting for the solar load and glazing/material properties throughout the proposed development.

Initially, a wind tunnel model was fabricated and tested at Windtech’s boundary layer wind tunnel facilities to determine the approaching flow conditions to the site. This data was then inputted as boundary conditions and used to validate the CFD model, which ensured the accuracy of the computational domain. The computational simulation was then run incorporating buoyancy effects, thermal models, glazing properties (including solar transfer through the proposed transparent canopies), as well as humidity and solar properties to assess the occupant thermal comfort within the development. This assessment was undertaken for various scenarios including summer day, summer night, shoulder season day and shoulder season night. The results of the study accurately modelled the thermal comfort of the outdoor regions within the development, illustrating the thermal comfort of the occupants with respect to Wind, Occupant clothing, Occupant Activity, Humidity and Universal Thermal Comfort Index (UTCI). The results indicated higher levels of thermal stress levels were present under the transparent canopies during the summer season. Where heat build-up was present due to air flow stagnation. Through the introduction of mitigation options such as adjustment of the height the canopies to be above the roof level of the retail pods to act as passive vents, flushing the hot air as well as changes to their material properties. This enabled the end thermal comfort conditions be deemed appropriate for the occupants. It is through detailed CFD modelling of this level that appropriate mitigation measures can be formulated without compromising the architectural design intent.

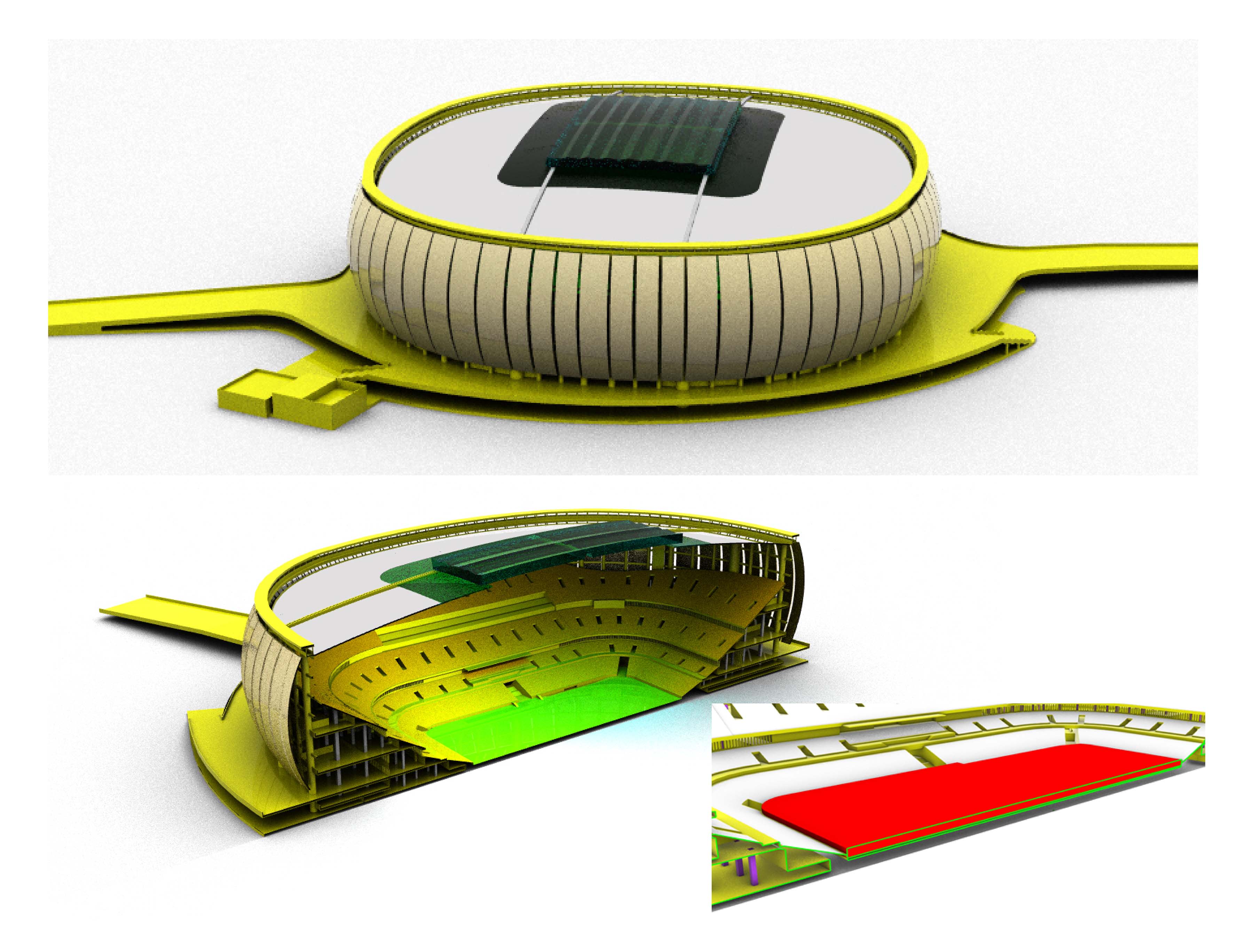

CASE STUDY 2: Jakarta International Stadium, Indonesia

Figure 3. Jakarta International Stadium, Indonesia – 3D CFD outdoor/indoor wind and thermal comfort model with porous façade, ETFE transparent roof, seating and pitch materials and Internal Thermal Load from occupants for music event.

The previously described hybrid wind tunnel and computational fluid dynamics (CFD) approach was also applied to the Jakarta International Stadium in Indonesia. A detailed analysis of the solar transfer through the semi-transparent ETFE roof was carried out for each of the ambient wind and environmental conditions. Furthermore, an additional simulation was carried out to replicate the heating load from the attendees of a sold-out music event.

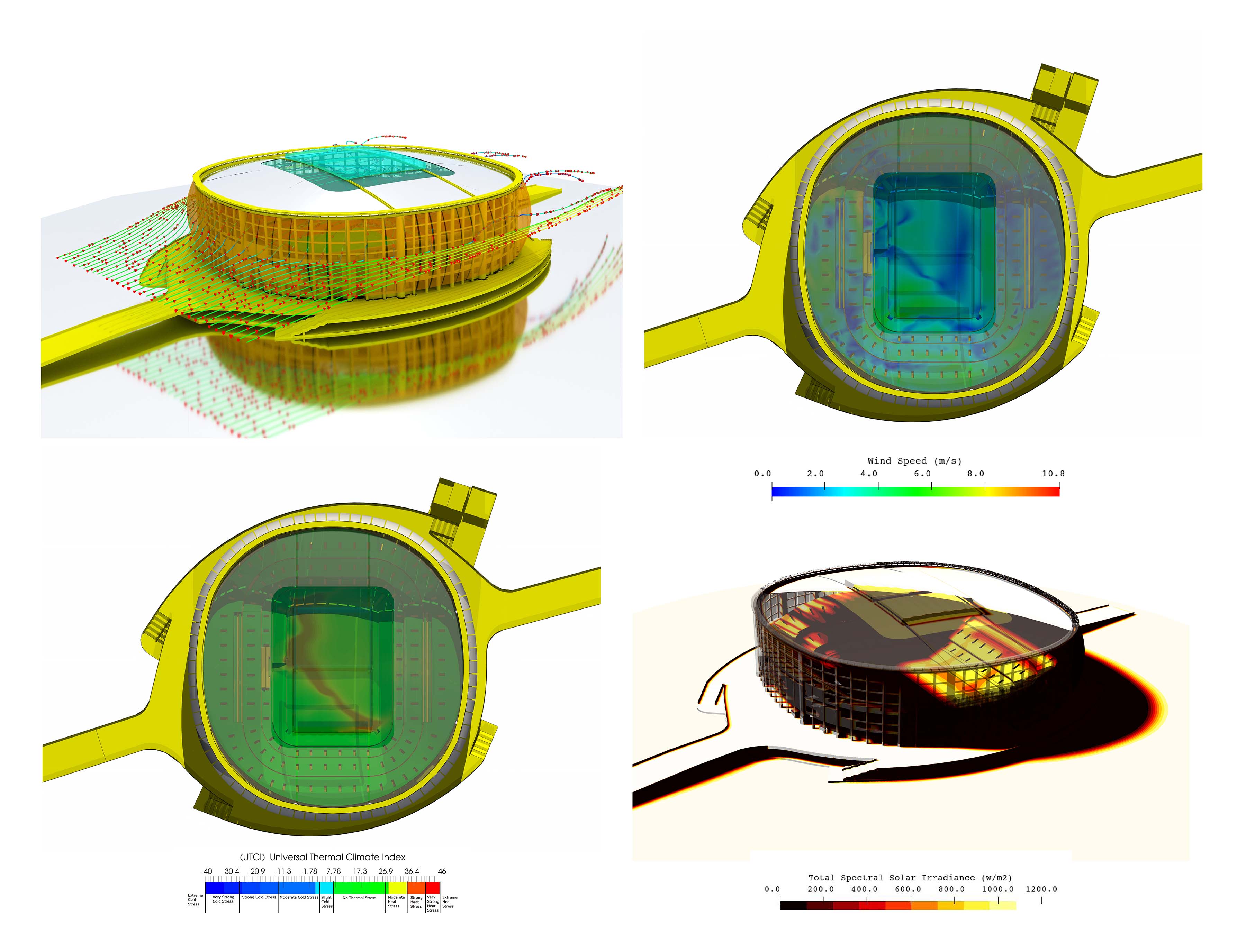

Figure 4. Jakarta International Stadium, Indonesia – External Wind Streamlines, plan view of interior occupied height Peak wind and UTCI and Peak Summer external solar irradiance.

WINDTECH’s unique approach of providing measurements from physical testing in the wind tunnel to form the accurate boundary conditions for further analysis using CFD is the main driver in our ability to provide a highly accurate multi-faceted solution. This then provides the appropriate tools during the design stage to identify problem areas and tailor solutions to mitigate adverse thermal comfort issues that could be experienced by end users, thereby avoiding the potential for expensive remedial measures post construction.

The results within the stadium indicated evaluated levels of thermal stress levels during the music event were present, but with the inclusion of slight adjustment to the transparent roofing system and additional façade porosity the end thermal comfort conditions were deemed appropriate for the occupants.