This month Greenland Australia and builders Probuild have completed Sydney’s tallest residential tower, the $700-million mixed-use Greenland Centre in the city’s CBD. The tower was designed by award-winning Australian architectural firms BVN and Woods Bagot.

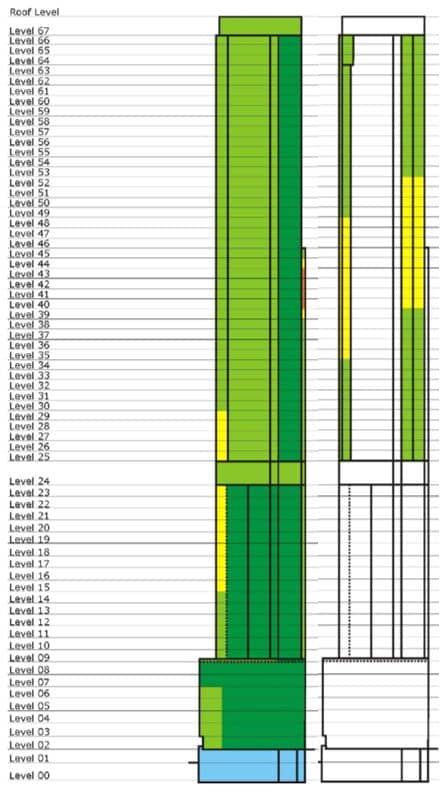

The building faced some unique challenges at the outset as pointed out by Andrew Johnson, the lead structural engineer from Arup Sydney, “It is the first building in the world that we are aware of where 45 stories have been grafted onto the top of an existing 25-story building, resulting in a slender tower of 10:1 aspect ratio integrating the existing structural frame and foundations into the redeveloped building.”

Andrew goes on to say that they were “constrained by the planning requirements of retaining the existing building structure—once the second tallest building in Sydney and completed in 1965—the structural design has integrated the original primary vertical steel structure into new composite columns, existing steel girders into the new low-rise floor structures, and augmented the deep pad footings founded on sandstone to support the higher gravity and wind loads of the new building.

Figure 1. The Model of the Greenland Centre (yellow) being tested in one of Windtech’s wind tunnel facilities in Sydney.

It was clear at the outset that the design constraints posed some interesting challenges from a structural design point of view. As such, there needed to be a collaborative approach adopted by all members of the design team. Tony Rofail, a Principal at Windtech Sydney Office quotes, “We needed to collaborate quite closely with the design team as we were embarking on a project that was atypical. Given the height, slenderness, and perceived structural dynamics of the tower, it was a given that it was bound for the wind tunnel. Testing of a preliminary massing of the tower in the wind tunnel very early in the concept design phase allowed the team from Arup to have a reliable indication of the lateral wind loads that they are up against for this very atypical structure to enable the selection of an appropriate structural system. The structural designer was then able to progress the structural design further prior to conducting a wind tunnel test of the final articulated design, where the actual wind loads came within 10% of the original assumptions and where the accelerations remained within the criteria for occupant comfort.”

Figure 2. The Completed Greenland Centre building at the corner of Pitt and Bathurst Streets, Sydney (image courtesy of the Urban Developer)

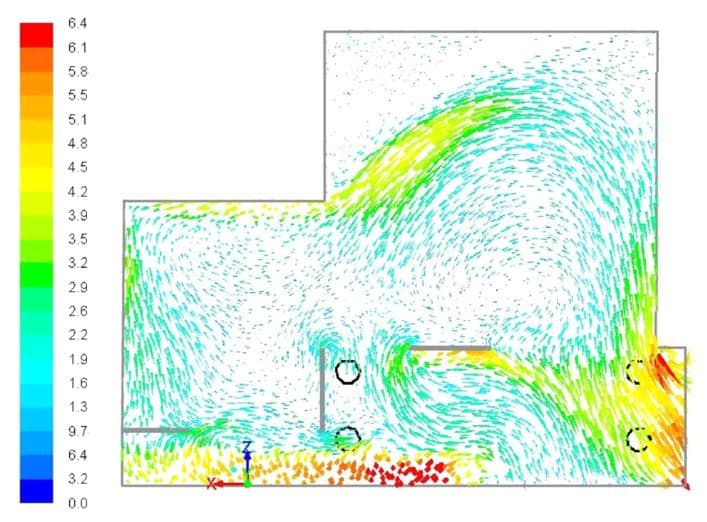

Another interesting feature of the development is the innovative balcony design put forward by the architects BVN and Woods Bagot. The unique glass-fronted ‘Sydney balconies’ conjure the idea of the quintessential verandah that can be used year-round. Windtech utilised a hybrid wind tunnel and Computational Fluid Dynamics (CFD) approach to test the concept, with remarkable results. This innovative design was demonstrated to have adequate wind comfort and natural ventilation under normal serviceability conditions, even at higher levels where wind tends to be more severe. Tony went on to say that “wind comfort and natural ventilation tend to compete with each other. However, we were able to demonstrate that this innovative design was able to achieve a healthy balance and gave the designers the confidence to create a seamless transition between the indoor and outdoor spaces which is a tricky proposition at these heights”.

Figure 3. Unique glass-fronted ‘Sydney balconies’ (image courtesy of the Urban Developer)

During the design process, Windtech had undertaken a diverse range of wind engineering studies for this development, including the following

We would like to congratulate the team made up of BVN, Woods Bagot, Arup, Probuild, Greenland, and many others for pulling off this unique and innovative award-winning project. It is truly an iconic Sydney development and will be for many years to come.

Figure 4. Pressure Contours for the northern aspect including pressures in the glazing behind the Sydney Balconies (Left Image: Outer Layer, Right Image: Inner Layer)

Figure 5. Wind Vector Diagram for one of the wind cases.

Figure 6. Smoke from BBQ location Number 3 with the effect of a weekly maximum westerly wind.

Figure 7. Smoke from BBQ location Number 4 with the effect of a weekly maximum westerly wind.

To enquire about our solutions relating to Wind Tunnel Testing and CFD Modeling, please reach out via our Contact us Page

To get regular updates on news and events, please follow us on our LinkedIn Page

Double skin façades are façade systems consisting of two layers, usually glass, wherein air flows through the intermediate cavity. This space (which can vary from 20 cm to a few meters) acts as insulation against extreme temperatures, winds, and sound, improving the building’s thermal efficiency for both high and low temperatures. One such example of a project with a double-skin facade is 30 St Mary Ax Building, “The Gherkin.”

The airflow through the intermediate cavity can occur naturally or be mechanically driven, and the two glass layers may include sun protection devices, such as blinds, either fully retractable or of a blade-type design.

While the concept of double-skin façades is not new, there is a growing tendency for architects and engineers to use them. Particularly in skyscraper design, they are favoured for their transparent façade, thermal and auditory comfort, reduced air conditioning costs, and elimination of the need for window-specific technologies.

Additionally, double-skin façades are adaptable to cooler and warmer weather. It is this versatility that makes them so interesting: through minor modifications, such as opening or closing inlet or outlet fins or activating air circulators, the behaviour of the façade is changed.

In cold climates, the air buffer works as a barrier to heat loss. Sun-heated air contained in the cavity can heat spaces outside the glass, reducing the demand for indoor heating systems.

Windtech conducts detailed Computational Fluid Dynamics (CFD) and Wind Tunnel testing, to assist in understanding the internal temperature, solar, and ventilation rates within various Double Skin Façade design makeups. The techniques lead to an overall detailed design in the material build-up in response to the achievable air-flow rates either mechanical or passive and the overall end reduction in solar/external temperature transfer.

Figure 1. Central Bank of Baghdad, Iraq (Image Courtesy of Zaha Hadid Architects)

Dr. Niall O’Sullivan a Technical Director at Windtech based out of the London Office indicated that “The new headquarters of the Central Bank of Iraq (CBI) comprises a podium and tower of 170 meters height and a gross internal area of 90,000 square metres. The structural exoskeleton frames the facade which is composed of an alternating pattern of open and closed elements, providing a variety of areas of light and shade within. The exoskeleton gradually opens and reduces as the tower rises, bringing greater lightness and views across the capitol. The project was designed by Zaha Hadid Architects and constructed by DAAX Construction”.

Windtech was responsible for the analysis of the mixed mode double skin façade design during the detailed design and construction documentation.

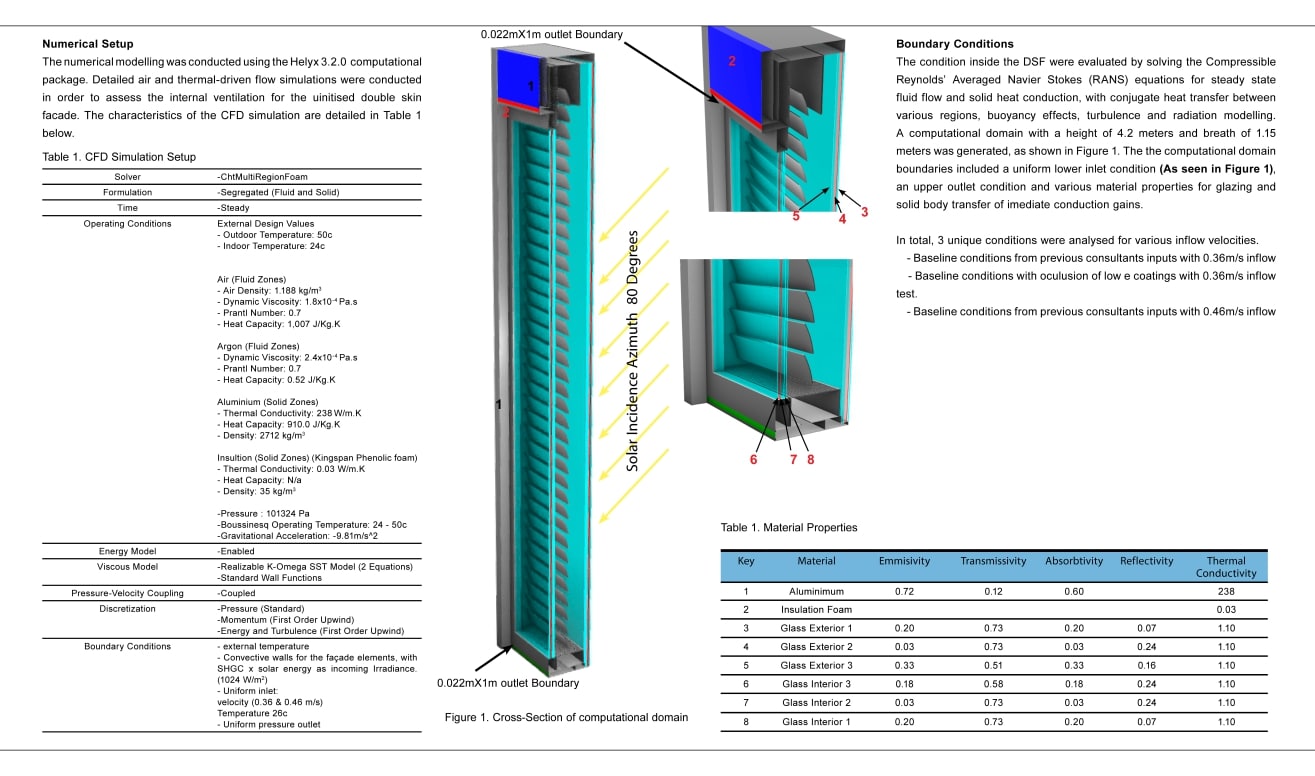

Dr. Niall O’Sullivan goes on to say “The detailed mixed-mode ventilation and solar thermal transfer CFD study was undertaken to investigate the solar transfer and the ventilation cooling rate prescribed in the current design. The simulation methodology including the material properties is included (in Figure 2). The simulations used the Conjugate heat transfer solvers available to calculate the solar and thermal transfer from the solid and fluid zones in the simulation domain. Through this, the internal building heat load could also be accounted for in the end simulations as well as the external solar transfer during the peak solar condition. All detailed glazing properties could be employed to define the solar loss through the façade build-up, where specific gas concentrations in each layer are defined to further the detail in the imposed thermal loss.”.

Figure 2. Computational Methodology

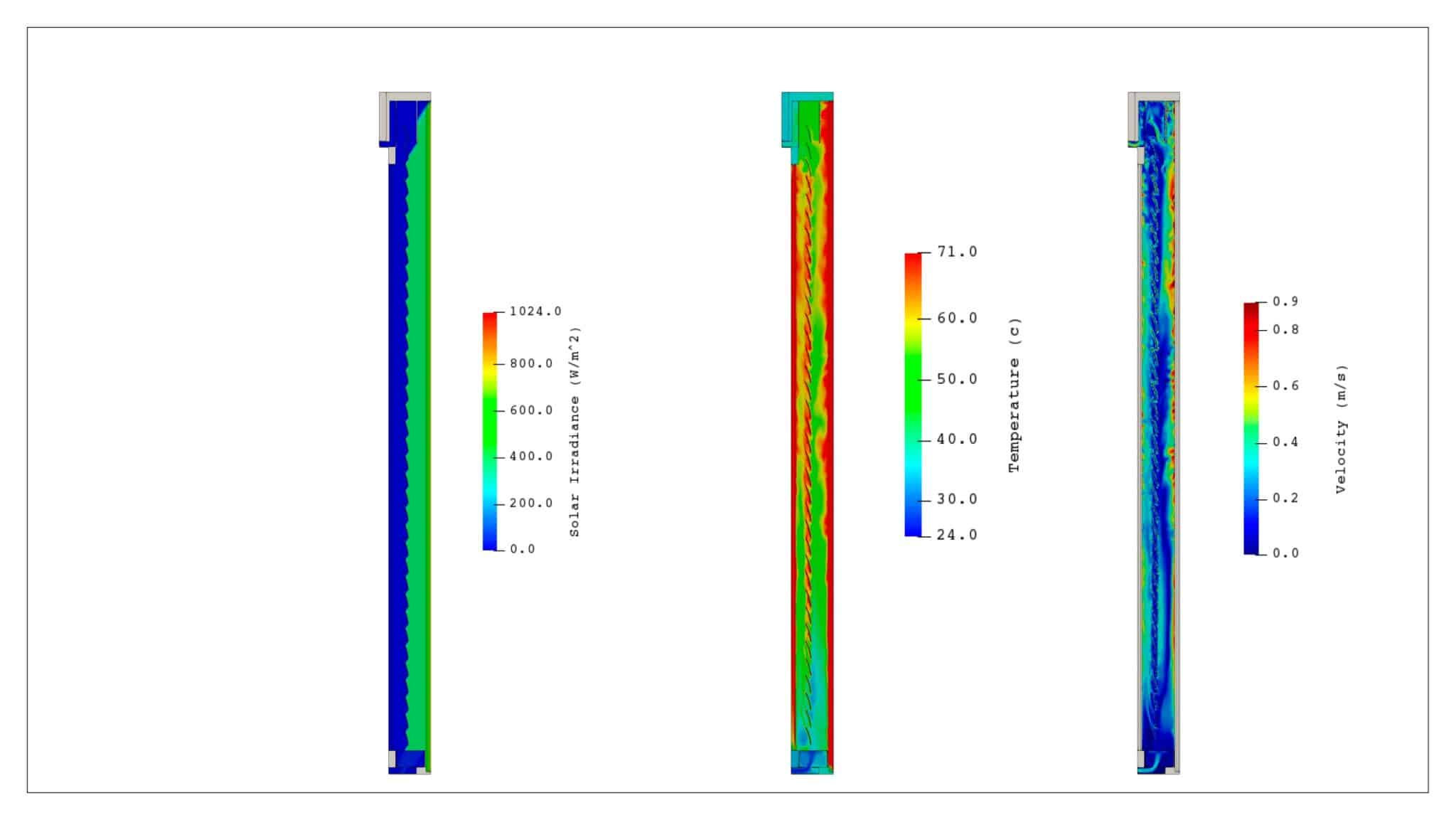

Figure 3. DSF Final Glazing Specification and 0.46m/s Inflow cross-sectional contours of solar irradiance, Internal Temperature and Velocity.

The outputs of the computational study presented the solar irradiance, internal cavity temperature and ventilation velocity. A selection of one of these simulations is shown in Figure 3.

The end result of the study led to the qualification of the designs effectiveness and further design adjustments in the glazing specification and ventilation rate imposed to allow for the double skin façades internal temperature to be within effective levels to maintain the overall internal buildings required heating performance during the peak seasons. It is only possible through the detailed analysis of this type for effective double-skin façade designs to be assured and implemented.

Windtech experience in this area of design led to the end clients design specification being assured and validated prior to construction.

To enquire about our solutions relating to CFD Modeling, please reach out via our Contact us Page

To get regular updates on news and events, please follow us on our LinkedIn Page

As a key contributor to the wind loads sub-committee acting for Standards Australia/Standards New Zealand, we would like to welcome the newest edition of “Wind Actions on Structures” under the new designation AS/NZS 1170.2:2021. This document will supersede AS/NZS 1170.2:2011.

The objective of this Standard is to provide wind actions for use in the design of structures subject to wind action. It provides a detailed procedure for the determination of wind actions on structures, varying from those less sensitive to wind action to those for which dynamic response are to be taken into consideration.

The objectives of this revision are to remove ambiguities, and to incorporate recent research and experiences from recent severe wind events in Australia and New Zealand.

Windtech Directors Tony Rofail and Dr Nick Truong, based out of our Sydney HQ, played an integral role in the upgrade of the standard, with Tony chairing the committee responsible for the review of Section 6 (dynamic response of tall, slender structures). Below is a non-exhaustive list of changes which were brought about though the efforts of Windtech staff:

A more complete overview of the changes can be obtained by downloading a preview of AS/NZS 1170.2:2021 at the following link: AS/NZS 1170.2:2021 Preview

Telemetry is not a new concept, and in fact was explored by James Watt in the mid 1700 when he added devices such as the mercury pressure gauges and the fly-ball governors to his steam engines; both classic examples of devices that would reveal something important about the performance of a system. The person consuming the data (in this case the operator of the steam engine) could then determine the best course of action depending on the “state” of the system in question.

Since then, monitoring has become commonplace across all industries due to the rapid progression of available technologies which were, in the recent past, only reserved for industries that were exposed to high capital expenditure or where there was a strict requirement to secure a high value asset. Nowadays these technologies are available to a broader spectrum of industries due to a significant reduction in cost. Further, with proliferation of Internet of Things (IoT) and universal communication protocols, these systems are no longer confined to Local Area Networks (LANs) but can be quickly and easily connected to the world wide web. This then opens the opportunity for a wealth of information that can be read in conjunction with (or correlated to) the main data that monitoring system was designed to produce.

It is then no surprise that the construction industry has recently been quick to adopt such technologies. One emerging application is in the area of Structural Health Monitoring (SMH), which is applicable to a range of different sub-industries as follows:

Another catalyst for the adoption of SHM in the construction industry has been the implementation of policies in various building codes. For example, the Indian Standard IS16700 “Criteria for Structural Safety of Tall Buildings” Clause 11 stipulates that a building taller than 150m shall be instrumented with accelerometers to monitor the impact that seismic and wind load have on the structural health. Further, Circular No. 01-2015 “Guidelines for implementing Rules on Earthquake Instrumentation for Buildings” which expands the scope of the P.D. 1096 “National Building Code of the Philippines (NSCP)” provides criteria on what types of buildings in seismic zones of the Philippines should include structural health monitoring for the purpose of building response to seismic activity, and to provide real-time alerts to occupants so they can be moved to safety under the Building Emergency Evacuation Plans (BEEP) instituted by the National Disaster Risk Reduction Management Council (NDRRMC).

SHM provides a platform to surface data that diagnoses the “state” of the constituent materials, parts, and assemblies that make up the total system. The central ideology is that the structure should perform within the bounds specified by the initial design, although some flexibility should be allowed for performance creep due to aging and/or general ware and tare of the structure. This is quite normal during the first 2-3 years of life given materials and/or structural systems bed themselves in which is more related to changes under normal serviceability conditions. However, there can be significant impacts on structural performance when a building or structure is hit by an extreme event (i.e. wind, seismic or other extreme events) where the actual load approaches the design load resulting in drastic changes in the structural performance due to the rapid degradation of the structure. This degradation could exhibit itself in many ways depending on the type of damage and/or the structural resilience. An example of degradation could be the on-set of micro cracking in concrete, which would increase total system damping while reducing the natural frequency. One of the ways to be able to pick up this effect could be to measure time-history response data using a highly sensitive accelerometer to log the change in the frequency of oscillation and the time to decay. This information can be plotted on a timeline to yield and indication of progressive or sever changes in the structural performance. Measured data can then be correlated with data from other sources either locally or externally (i.e.wind speed data) to allow for a diagnosis the reason why the structure was performing outside the normal parameters, thus helping to dictate strategies around service and maintenance.

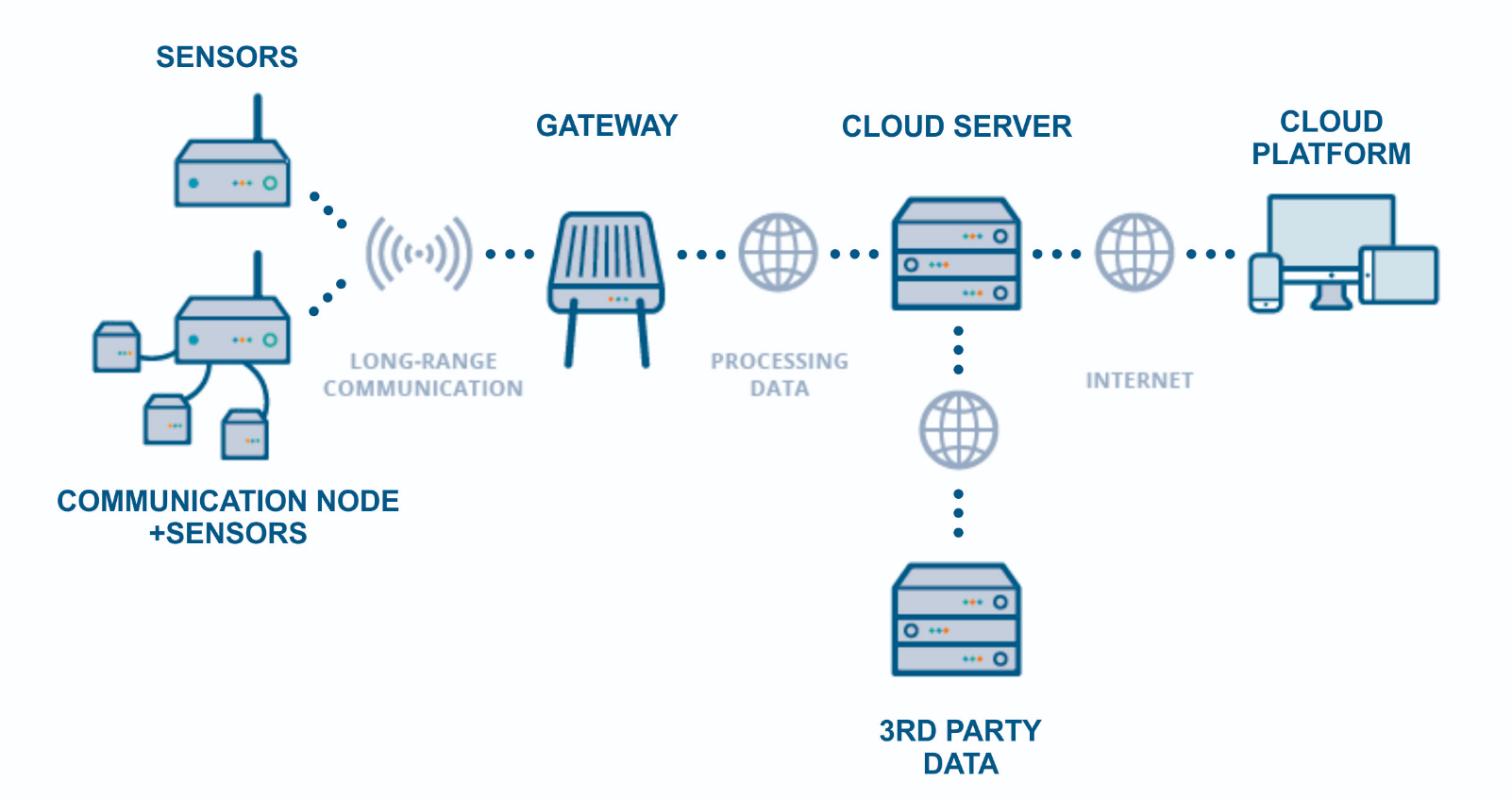

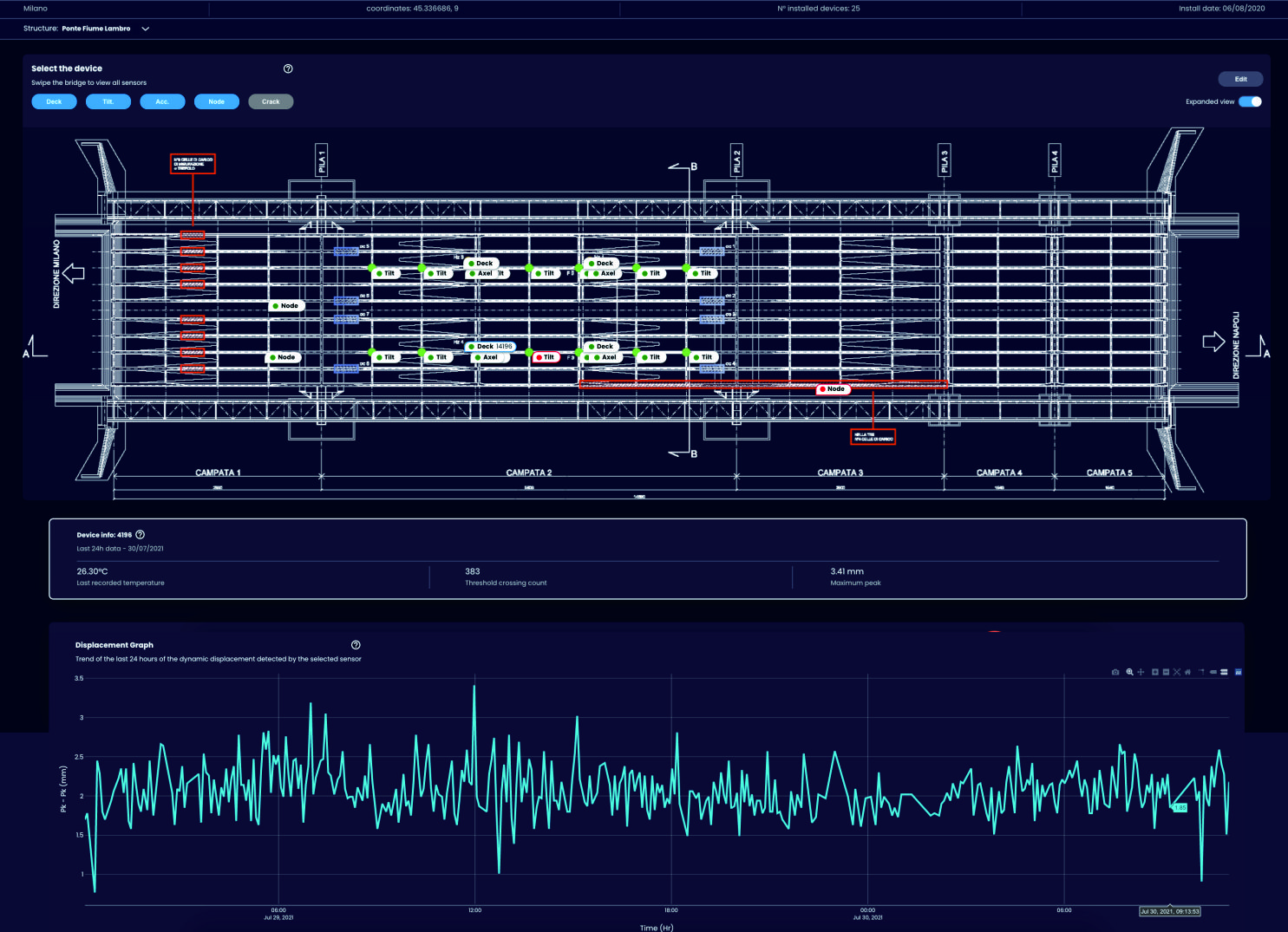

SHM can be seen as a new way to conduct non-destructive evaluation. Further it may not be limited to monitoring a single data point at a single location, but rather a string of data points over time from vast array of sensors of different type and location in order to paint a complete picture of the structural health. Although the design of SHM system can vary depending on the individual project requirements, this tends to follow the typical blue print indicated in Figure 1, where a mixture of sensors feed data into digital or analogue nodes which transmit the information to a gateway. The data is then processed and formatted, sent via the internet to a cloud server and consumed via cloud platform that helps the user navigate the data in a structured way. An example of a cloud platform can be seen in Figures 2a and 2b. In addition to the consolidation of local sensor data, 3rd party information (i.e. regional wind climate data) can be fed into the system to enrich the underlying data model.

Figure 1. Structural Health Monitoring Blueprint

Some sensors that are being used in the industry, and by Windtechcan be seen below:

Figure 2a. Cloud Platform Showing Real-time Acceleration Time Response Data

Figure 2b. Cloud Platform Showing Real-time Displacement Data

Aaron Lefcovitch a Director at Windtech based out of the Singapore Office indicated that “knowing the health of a structure, whether it is a tall building, or a long-span bridge provides multiple benefits. It allows for manufactures, owners, end users, building designers and maintenance teams gain real-time insights into the performance of their assets. We are now able to stream and process large amounts of data using available technologies to foster informed decisions. This allows us to ensure that assets are performing within the design parameters. Data can be analysed in real time and can trigger events or notifications that instantly allow performance-based (or condition based) decisions. This reduces the cost of labour, human error, inspection costs and rectification work where there in some cases be no material defect. It also increases the value of the structure or asset, improves structural reliability and enables the implementation of effective performance-based design approaches which have major impacts on both the robustness and efficiency of the structure, and cost of construction. It also allows for building designers to collect full-scale data, so they are able to compare and fine tune their theoretical models and analysis techniques. The benefits are really limitless”.

SHM has ushered in a new era for construction industry. The concept of smart or intelligent materials/structures has become more present in the minds of designers and is being embraced by private and government institutions around the world as being a significant step forward in the general evolution of the construction industry. Windtech is proud to be part of this evolution with the implementation of their own solutions in the SHM space and will continue to encourage the implementation of evidence or performance-based approaches at all stages of a project’s lifecycle.

To enquire about our solutions relating to Structural Health Monitoring, please reach out via our Contact us Page

To get regular updates on news and events, please follow us on our LinkedIn Page

Wind and temperature differentials can cause unexpected results for tall buildings located in hot and/or cold climates. If not properly accounted for issues such as frequent jamming of lift doors and uncomfortable internal wind conditions in lobbies and main entrances can occur. These issues were anticipated by the project team behind the Resorts World, Las Vegas project.

Fusing three premium brands – Hilton Hotels & Resorts, LXR Hotels & Resorts and Conrad Hotels & Resorts – Resorts World, Las Vegas is targeting to open in the Summer of 2021.

Designed by Steelman Partners, this $4.3 billion resort will feature a 110,000ft2 casino floor, 3,500 guest rooms and luxury suites and a 5,000-capacity theatre, plus much more. The project team included DeSimone Consulting Engineers, Enclos and Corte Cladding Consultants, and Windtech were thrilled to be an integral member of the team.

With such a high-end development, ensuring a reliable,efficient, and comfortable indoor and outdoor environment was an essential target for Resorts World, who have been rolling out developments all over the world for many years.

(Background image courtesy of rwlasvegas.com – Inset image courtesy of Windtech Consultants)

Windtech was invited to conduct a wide-ranging scope of wind tunnel testing for the design and optimisation of the structural and cladding systems, and also looked at various environmental effects such as how to solve air quality issues using passive stack effect.

The stack effect or reverse stack effect are caused when there is a temperature differential between the internal conditioned areas of the building and the outside air. When the internal air is warmer than the external conditions, air is drawn in at the lower levels and rises within the building, this is the stack effect. The reverse stack effect occurs when the inside of the building is cooler than then external air and air flows out of the lower levels of the building. Vertical air flows within the building are also driven by the external façade pressurisation of the building.

These two effects are commonly experienced at the ground level entrances or lift doors for high-rise structures during the cooler months of the year for the stack effect and during the warmer months of the year for the reverse stack effect. Additionally, flows may occur at ground level entrances or lift doors driven only by the wind driven external pressurisation of the building under any temperature conditions. For developments that are not particularly tall and located in a temperate climate, it can been assumed that any internal air flows driven by temperature only will be negligible and flows driven by thermal forces only not considered.

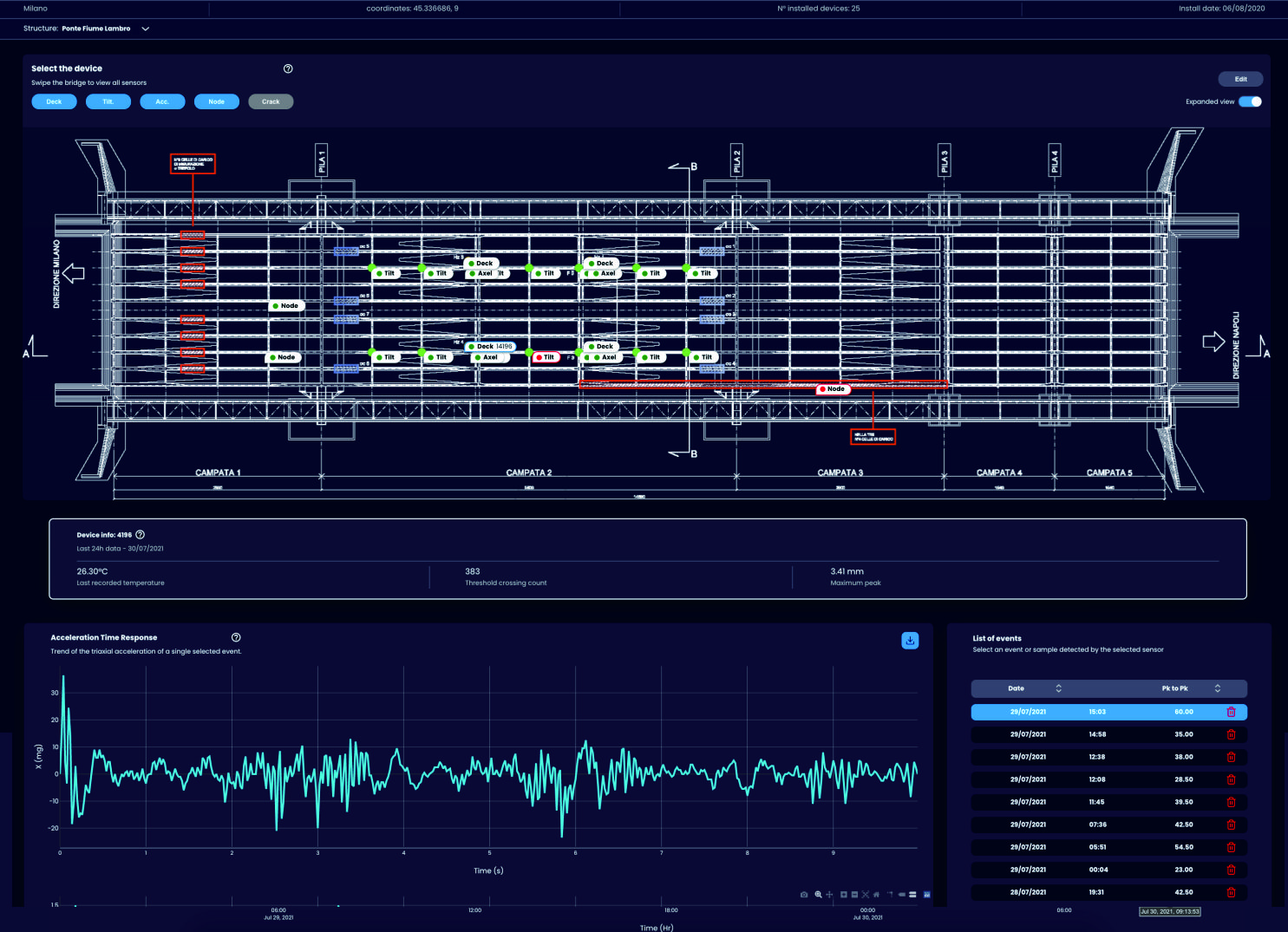

Fig 1. Ground Floor modelled flow rates and typical data outputted for various aspects of stack effect phenomenon throughout the building envelope for the summer season. (Note: image above is not of Resorts World)

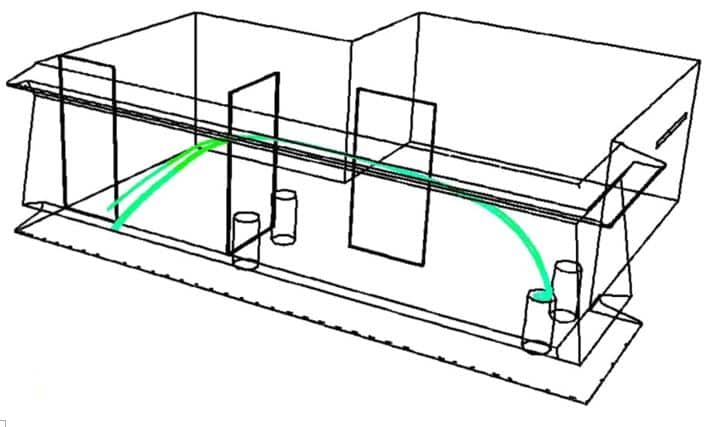

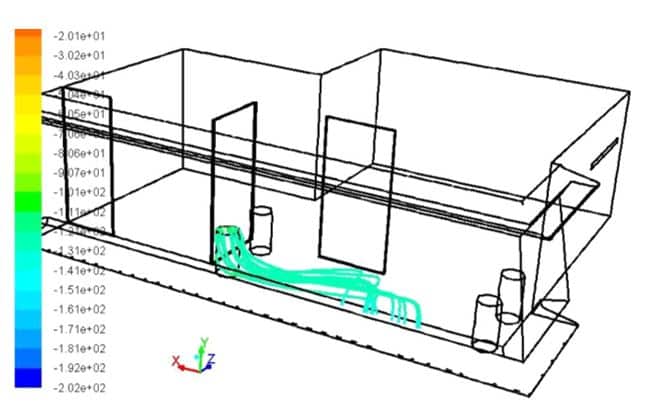

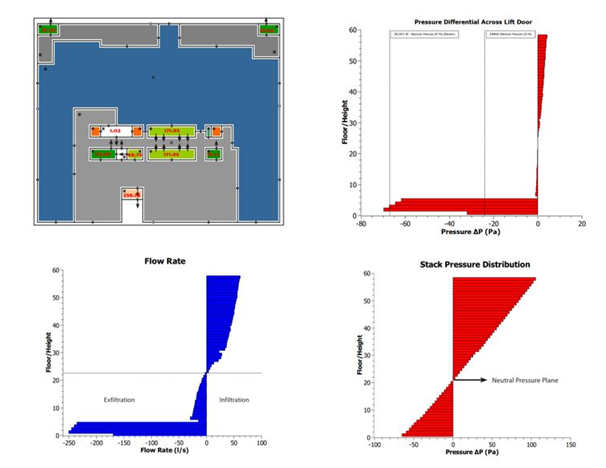

Aaron Lefcovitch, a Director at Windtech’s Singapore office comments “It is important to be able to measure the impacts of stack effect, as uncontrolled air movement within a building tends to hamper the performance of lift and access doors, mechanical and fire systems, and can even cause undesirable wind conditions at key entrance locations around the building.However, in this exciting example the client was proactive in anticipating the potential issue of smoke propagating from the casino floor to other areas of the building, namely the hotel lobby. Traditionally these issues are solved by designing expensive mechanical systems, however we were able to help the client design a passive system which utilised the power of nature and the stack effect”.

Fig 2. Ground Level Smoke Concentrations

Windtech undertook a detailed study that combined pressure data from the wind tunnel, computational modelling of smoke dispersion on the casino gaming floor and a numerical analysis of stack effect which identified the existence of smoke infiltration into the hotel lobby areas during a calm day in winter. It was concluded that this effect could be mitigated by adjusting the amount of supply and return in the HVAC systems – a simple solution to complex problem.

Windtech was pleased to work with such an esteemed group of consultants for a client that supported a value engineering approach to solve a complex problem.

Another interesting study undertaken for this project include the assessment of the impact of building accelerations for occupant comfort as well as lift operation. Other studies include wind loads and tip deflections under design wind loads and cladding pressures on the façade as well as the LED systems that are to cover the facade of the development (see inset image above) as well as an extensive wind environment study.